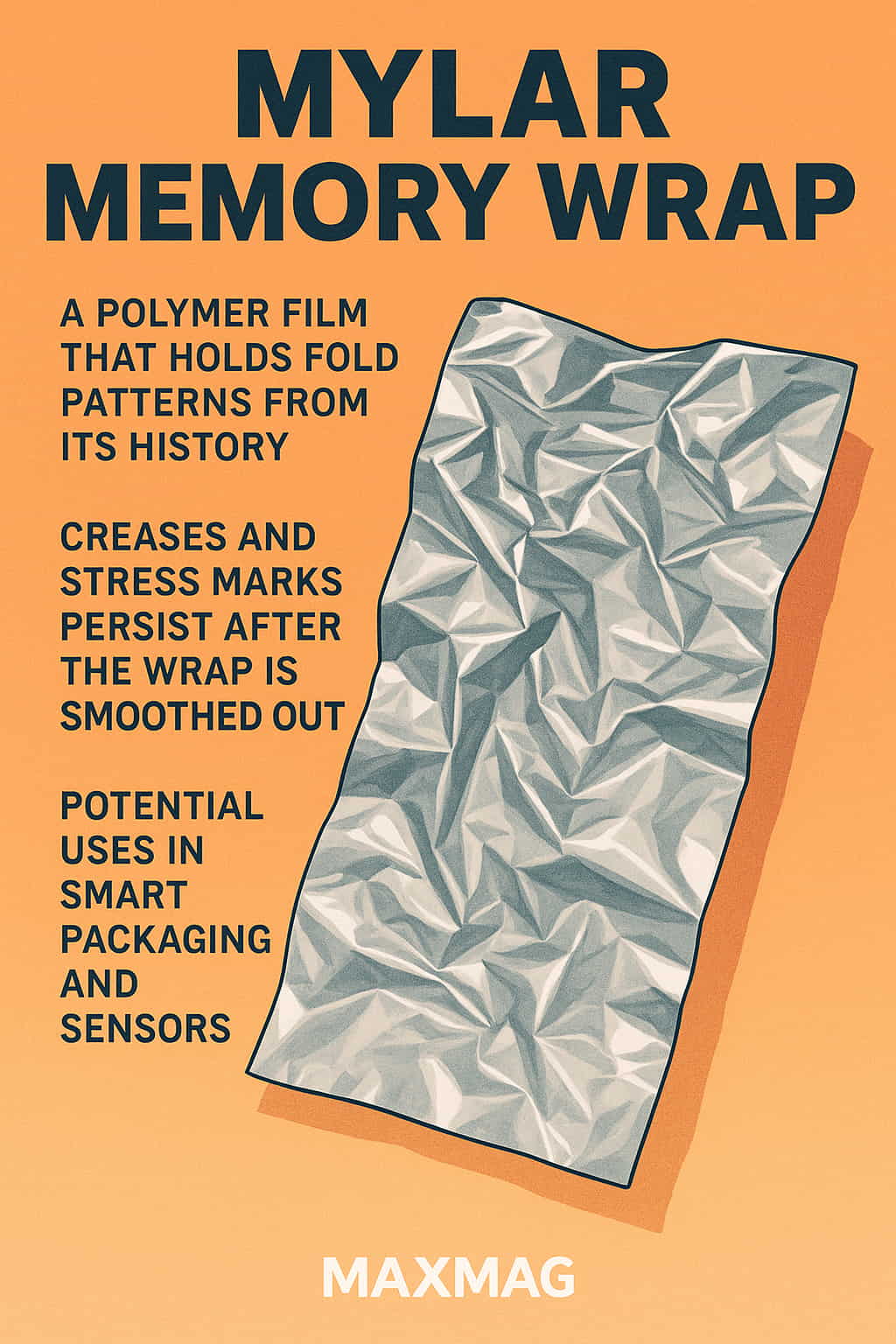

On the surface, it looks like nothing more than a crinkled piece of shiny plastic. But under the microscope and through the lens of modern science, that seemingly simple material tells a fascinating story. A new wave of research has revealed that some forms of Mylar — a widely used plastic film — can retain the memory of its folds, creases, and stress patterns over time. This phenomenon, now dubbed the Mylar memory wrap, is reshaping how scientists and engineers think about packaging, materials science, and even the future of smart surfaces.

What is a Mylar Memory Wrap?

Mylar is a type of polyester film made from stretched polyethylene terephthalate (PET). It has long been used in balloons, food packaging, emergency blankets, and various industrial applications. Known for its strength, flexibility, and high reflectivity, it is prized for both its functional and aesthetic qualities.

But a new discovery is giving Mylar a fresh reputation — that of a material with memory.

When this plastic wrap is folded or crumpled, it doesn’t simply return to a neutral, smooth form. Instead, it retains subtle, persistent imprints of its handling history. These are not just visible wrinkles, but microscopic deformations stored in the polymer’s internal structure. Researchers have named this effect the Mylar memory wrap — a type of physical “recall” embedded in the film itself.

The Science Behind the Memory Effect

To understand how the Mylar memory wrap functions, one must explore the fascinating behavior of polymers under stress. When a flexible plastic like Mylar is bent, folded, or compressed, the long-chain molecules within the film shift and realign. In normal conditions, these molecules relax back into place once the stress is removed. But under certain circumstances — especially repeated stress or extreme folding — these shifts become semi-permanent.

This structural locking creates internal tension zones that don’t immediately revert. Even if the Mylar is smoothed out and appears flat, these molecular “scars” remain imprinted within the film. Over time, and especially under certain temperatures, the plastic may gradually relax and recover some of its original state. But the recovery is incomplete. In many cases, the material visibly and invisibly “remembers” how it was previously handled.

Scientists studying this effect have used atomic force microscopy and thermal imaging to detect and measure the residual patterns, confirming that Mylar is more than just a passive medium — it’s a dynamic material capable of retaining data through physical stress.

H2: Why the Mylar Memory Wrap Matters

The implications of this discovery extend far beyond mere curiosity. If a material like Mylar can store information about its handling history, it opens the door to new applications in sensing, monitoring, and diagnostics.

Imagine packaging that can reveal whether it has been tampered with. A food wrap that indicates how many times it has been opened. A biomedical sensor that tracks pressure exposure over time. These are not futuristic fantasies — they’re practical uses of the Mylar memory wrap effect, harnessing the natural responses of a humble polymer.

This discovery is also a reminder that materials we often take for granted can hold hidden complexities. According to a report from the American Chemical Society, polymer memory effects are an emerging field of interest with potential crossover into wearables and flexible electronics.

Real-World Applications on the Horizon

-

Smart Packaging: Companies are increasingly exploring ways to monitor product handling through packaging itself. A Mylar memory wrap could offer visual or sensor-based cues indicating whether a package was bent, dropped, or tampered with — useful in pharmaceuticals and perishable goods.

-

Anti-Counterfeit Measures: High-end goods could be wrapped in materials that record movement or stress, making it easier to detect if a product was unsealed and resealed.

-

Biomedical Sensors: Wrappable, lightweight sensors using memory films might help track patient movements or pressures exerted on bandages or dressings.

-

Data Storage and Soft Robotics: Research from MIT’s Materials Research Laboratory has even speculated about using polymer memory effects in soft robotics or analog data storage, though that remains in experimental stages. Visit MIT News for more about such innovations.

H3: How the Mylar Memory Wrap Was Discovered

The discovery came from an unexpected observation. A group of researchers noted that even after smoothing a crumpled piece of Mylar, faint waves and marks were still detectable. They wondered — was this mere surface damage, or something deeper?

By using sensitive microscopes and thermal tracking, they observed how these marks responded to heat and pressure. The patterns were not random. In fact, the plastic “relived” its past handling in detectable ways, almost like a fingerprint of experience.

This raised an exciting hypothesis: could Mylar actually “remember” its physical history? Controlled experiments confirmed that the material indeed displayed consistent memory patterns, resistant to time and moderate heat.

The Role of Time and Temperature

Interestingly, time plays a key role in how this memory is stored and lost. Over short intervals, the plastic holds onto its deformations strongly. But with increased time and exposure to higher temperatures, it gradually “forgets” its past folds.

Still, this doesn’t mean the memory is entirely erased. Just as old scars fade but never completely vanish, the Mylar memory wrap retains a ghost of its former shape. For researchers and engineers, this means that memory duration and erasure can potentially be engineered — a huge advantage for building future smart materials.

A Closer Look: Experiments in Material Memory

To better understand how this material behaves, scientists have subjected Mylar to repeated folding and unfolding, tracking how well it “remembers” each event. The results show that memory is cumulative: the more the material is crumpled, the deeper and more lasting its internal record becomes.

Additionally, researchers have found that the direction of folding affects memory retention. Folds along a single axis are more likely to embed a clear pattern than chaotic scrunching. This gives designers a possible way to code or pattern information into materials just by folding them in specific ways.

Could Mylar Record More Than Just Shape?

While Mylar’s memory today is limited to shape deformation, scientists are exploring whether it could be used to encode other types of data. For example, by combining memory films with ink that responds to pressure or heat, it may be possible to create hybrid systems where mechanical memory triggers a visible or electronic response.

This could be especially useful in fields like logistics or medical diagnostics, where the history of a product or patient needs to be tracked without adding complex hardware.

Limitations and Questions Still to Be Answered

Like all emerging technologies, the Mylar memory wrap comes with caveats. First, the memory isn’t truly digital — it doesn’t store binary code or readable text. Second, environmental factors like humidity and temperature affect how reliably the memory is retained.

Also, while fold memory is visually detectable, it requires specialized equipment (such as high-resolution microscopes or surface scanning lasers) to precisely read the deeper memory patterns. This limits its immediate use outside laboratory or high-tech environments.

Nevertheless, these are engineering challenges — not scientific dead ends. With further study and refinement, Mylar memory films could one day be incorporated into everyday objects in ways we haven’t yet imagined.

The Future of Smart Materials Begins with the Ordinary

One of the most exciting takeaways from the Mylar memory wrap is this: innovation doesn’t always come from the invention of new materials. Sometimes, it comes from understanding the overlooked behaviors of ones we already use.

Mylar has been around since the 1950s. But only now are we beginning to understand its full potential — not just as a wrapper, but as a witness. A silent observer that keeps a record of what it’s been through.

In a world increasingly driven by data, memory, and monitoring, the ability of materials to store experience is a powerful and underexplored frontier.

FAQ: Mylar Memory Wrap

What is a Mylar memory wrap?

It’s a polyester film that can retain fold and stress patterns from previous handling, effectively “remembering” how it was used.

How does it store this memory?

Through semi-permanent molecular shifts and internal stress zones in the plastic’s polymer chains, especially after repeated folding.

Can this memory be erased?

Partially. Heat and time can gradually relax the stored tension, but traces of the past typically remain detectable.

What could this technology be used for?

Potential applications include smart packaging, anti-counterfeiting wraps, flexible sensors, and experimental robotics.

Is this already being used commercially?

Not yet in mainstream products, but ongoing research is pushing toward real-world applications in materials science and engineering.